From small parts to entire assemblies, Centerline will work with your team to design and model any project for fast and reliable prototyping and pre-production testing. Centerline can work quickly through these processes to create your part from traditional materials without the uncertainties of 3D printed parts that cannot go through the entire gamut of testing.

Centerline will source the materials for your job whether it is a few pieces for prototyping or thousands for large scale production runs. Our large supplier network allows us the flexibility to sourcing from multiple vendors, if need be, during supply chain constrained times.

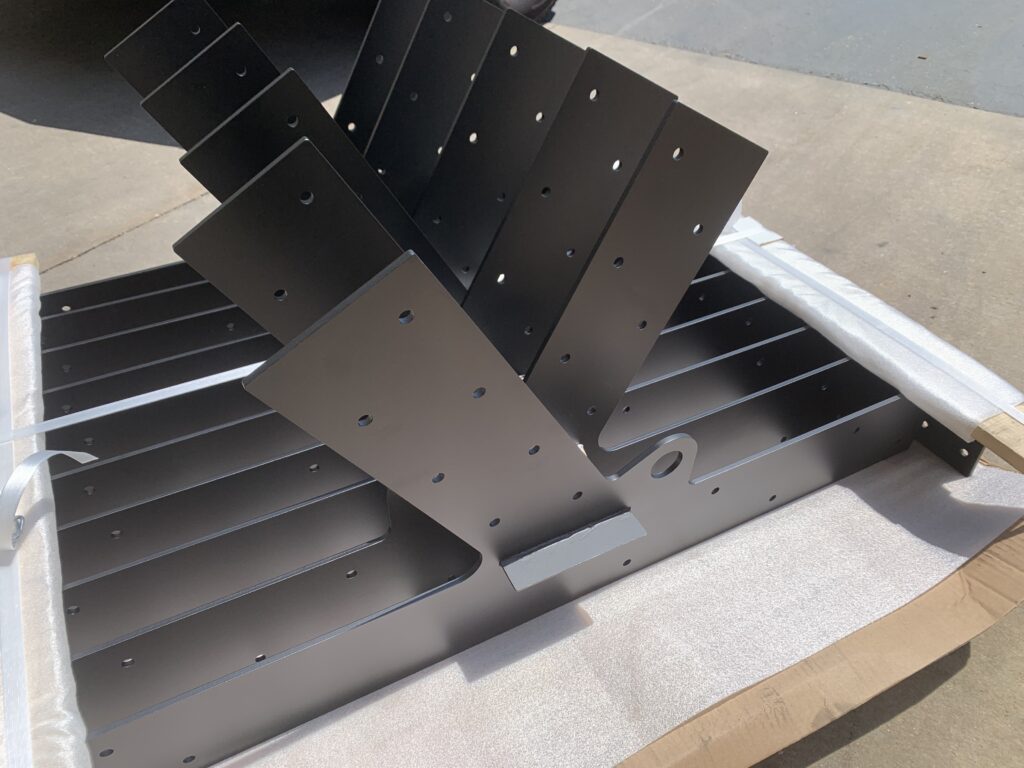

Through our turnkey system Centerline can quickly and efficiently have component parts either laser, plasma, oxy-fuel, or waterjet cut. We are also able to accommodate parts requiring multi-axis machines such as tube.

From mild steel to stainless to brass, we can have your parts formed with precision.

Centerline offers a wide variety of welding processes to meet your requirements, including; FCAW, SMAW, GMAW, GMAW-P, GTAW, OAW, RSW.

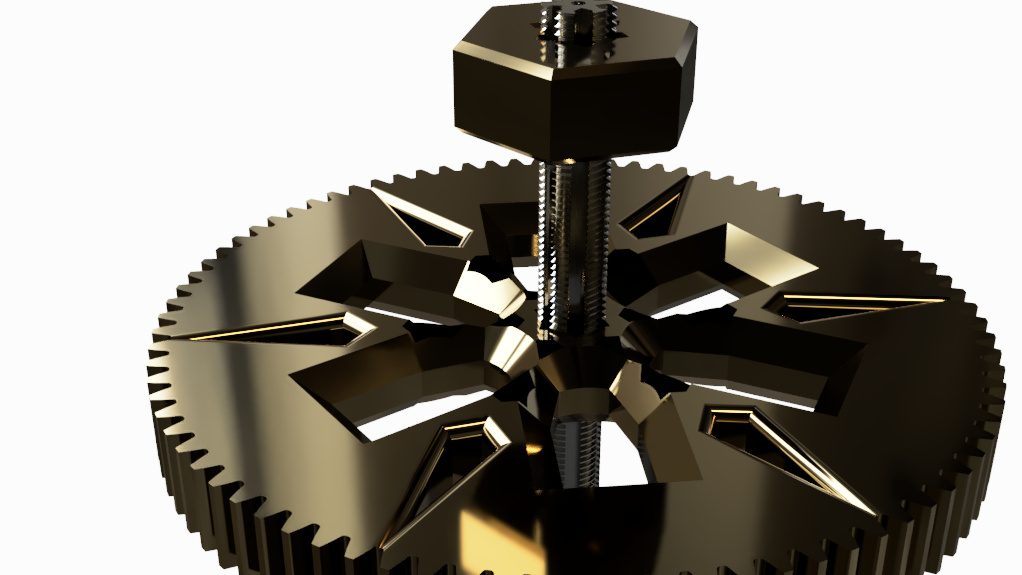

From prototyping parts to full scale production runs, you will find Centerline to be a trusted partner in a wide variety of machining processes.

We offer a wide variety of product finishes from powder coat, industrial lacquers, hot dip galvanizing and anodizing, to polishing and other standard non coated finishes. Whatever finish your product may require, we’ve got it covered.

Office Main

(414)-307-4350

Facility Location

1123 E Rawson Ave.

Building C

South Milwaukee WI 53172

©ALL RIGHTS RESERVED